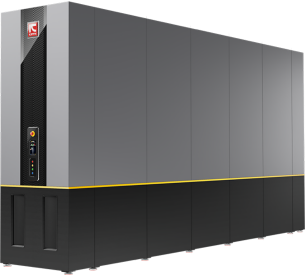

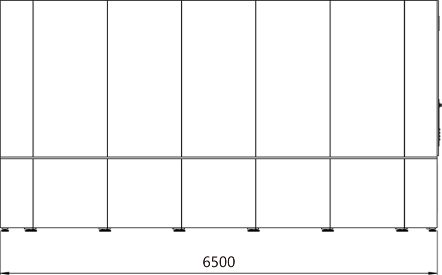

Model

NESTS-SMD-SK

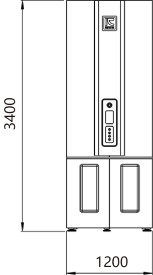

Size

L*W*H:6500mm*1200mm*3400mm,supports customization

Electrical parameters

Voltage:AC220V,Power:1600W(MAX),UPS optional

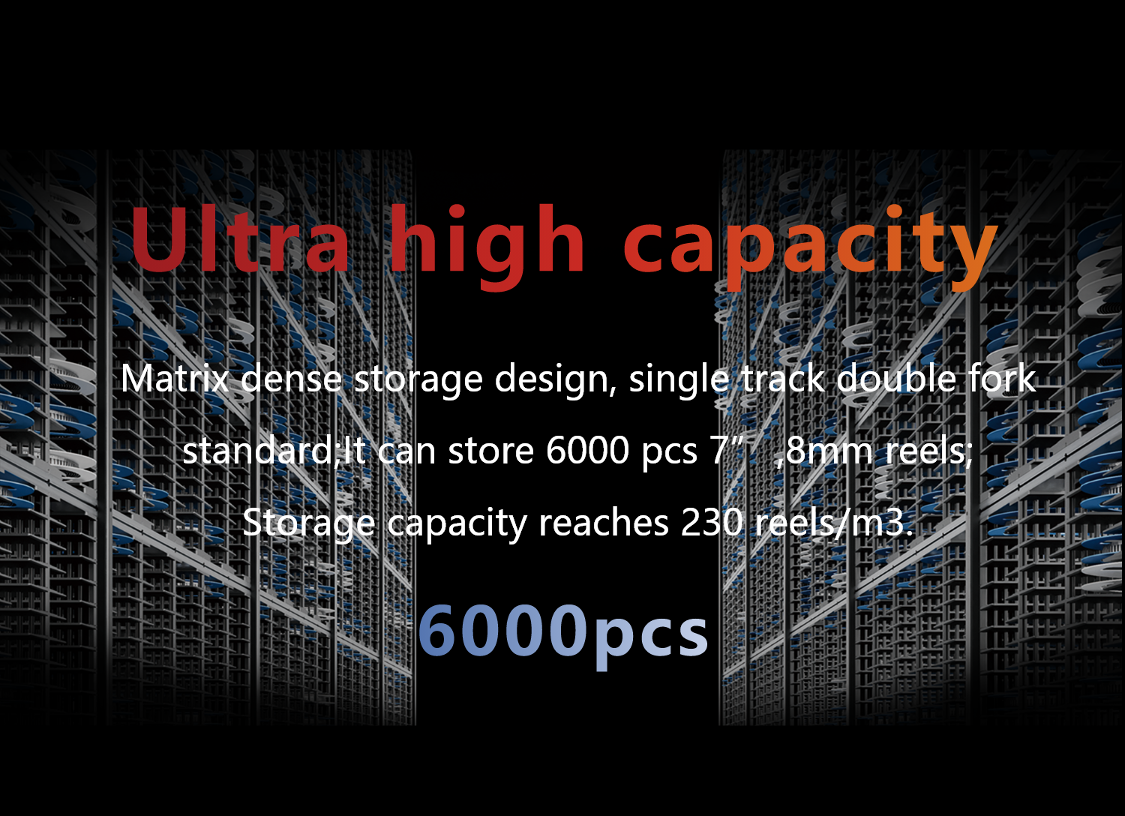

Storage capacity

7" 8mm reels: 6000 reels, compatible with other thickness combination , supports customization.

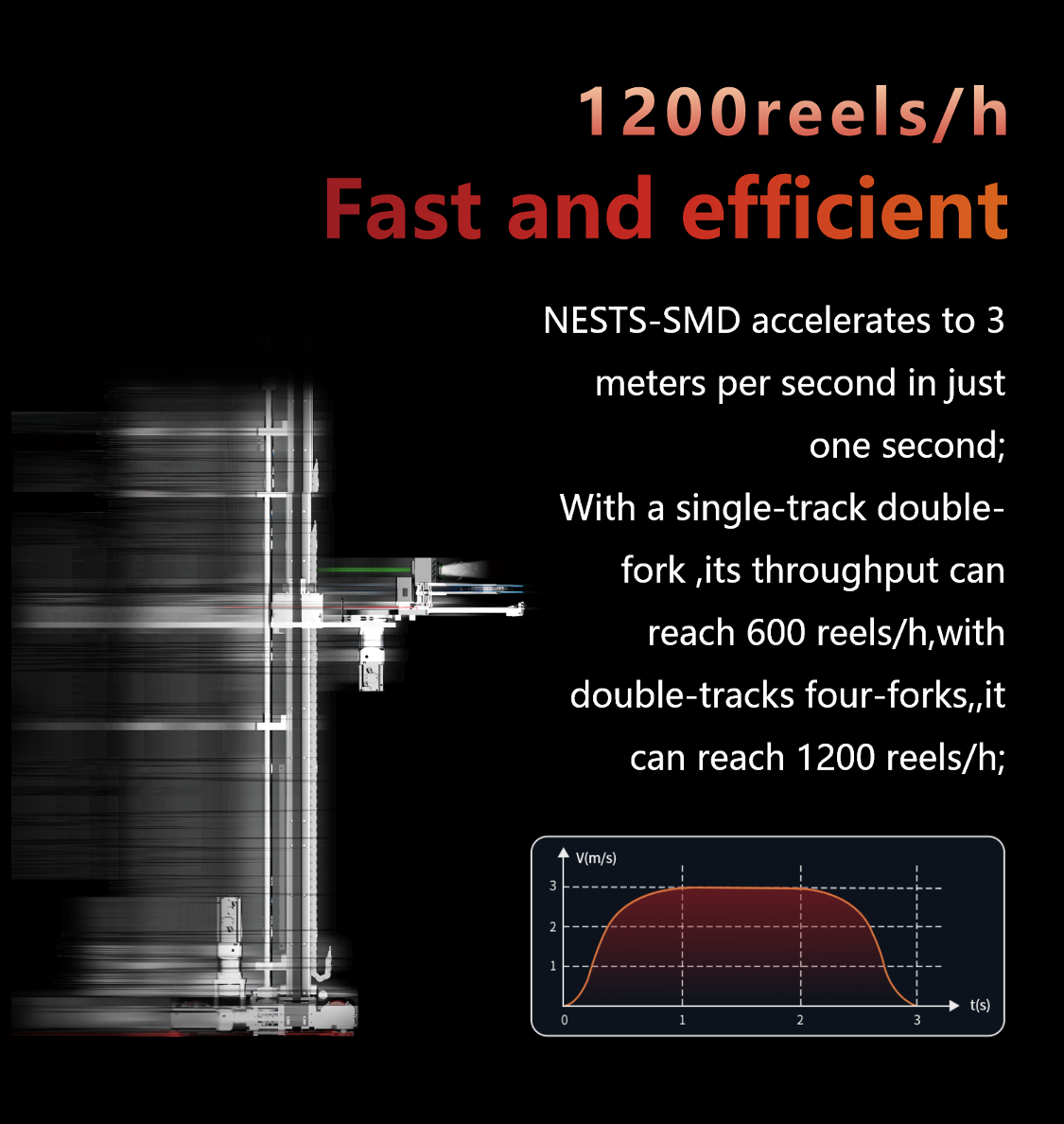

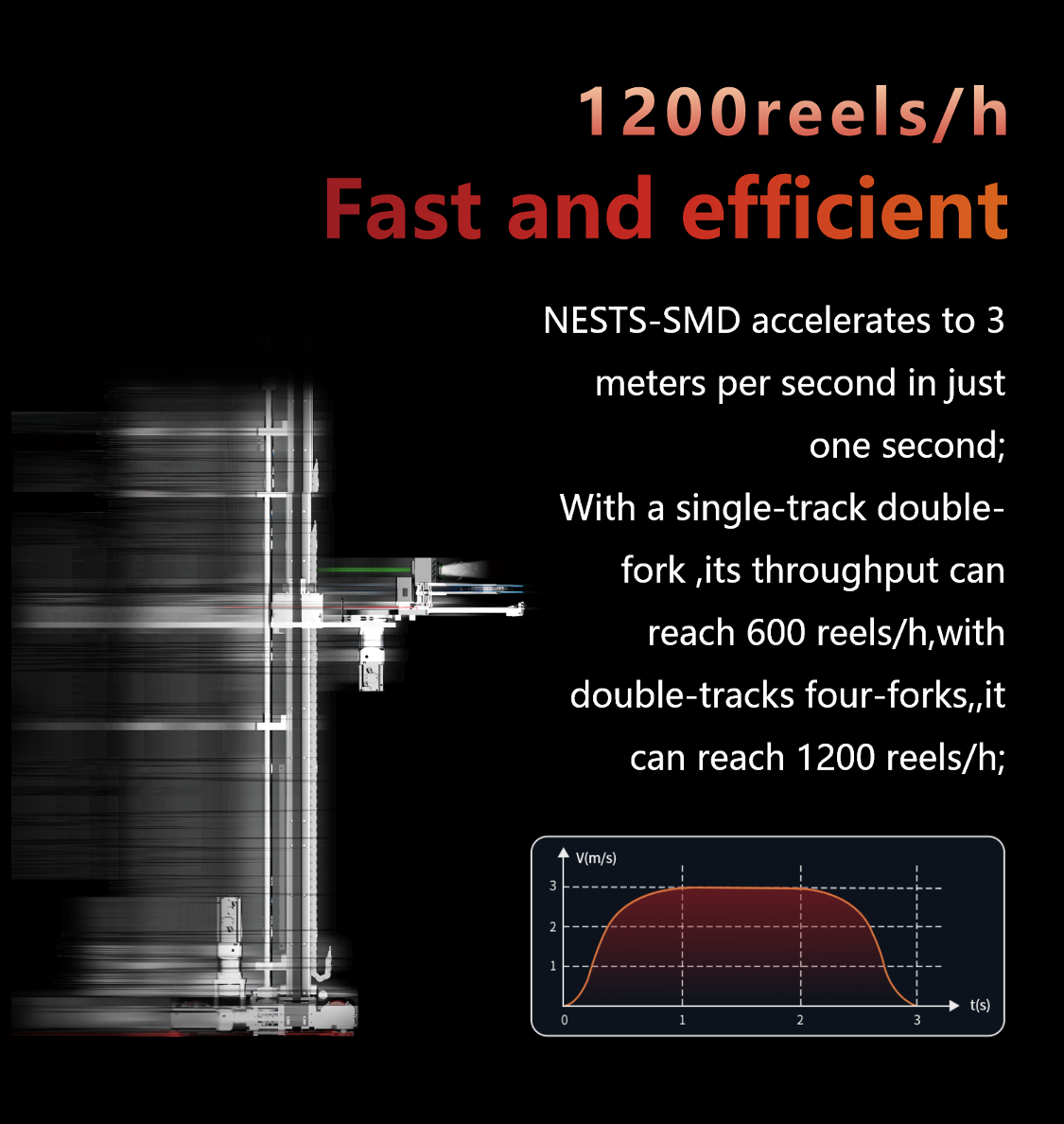

Throughput capacity

high speed: minimum 600 reels/h, ultra-quiet mode: minimum 400 reels/h

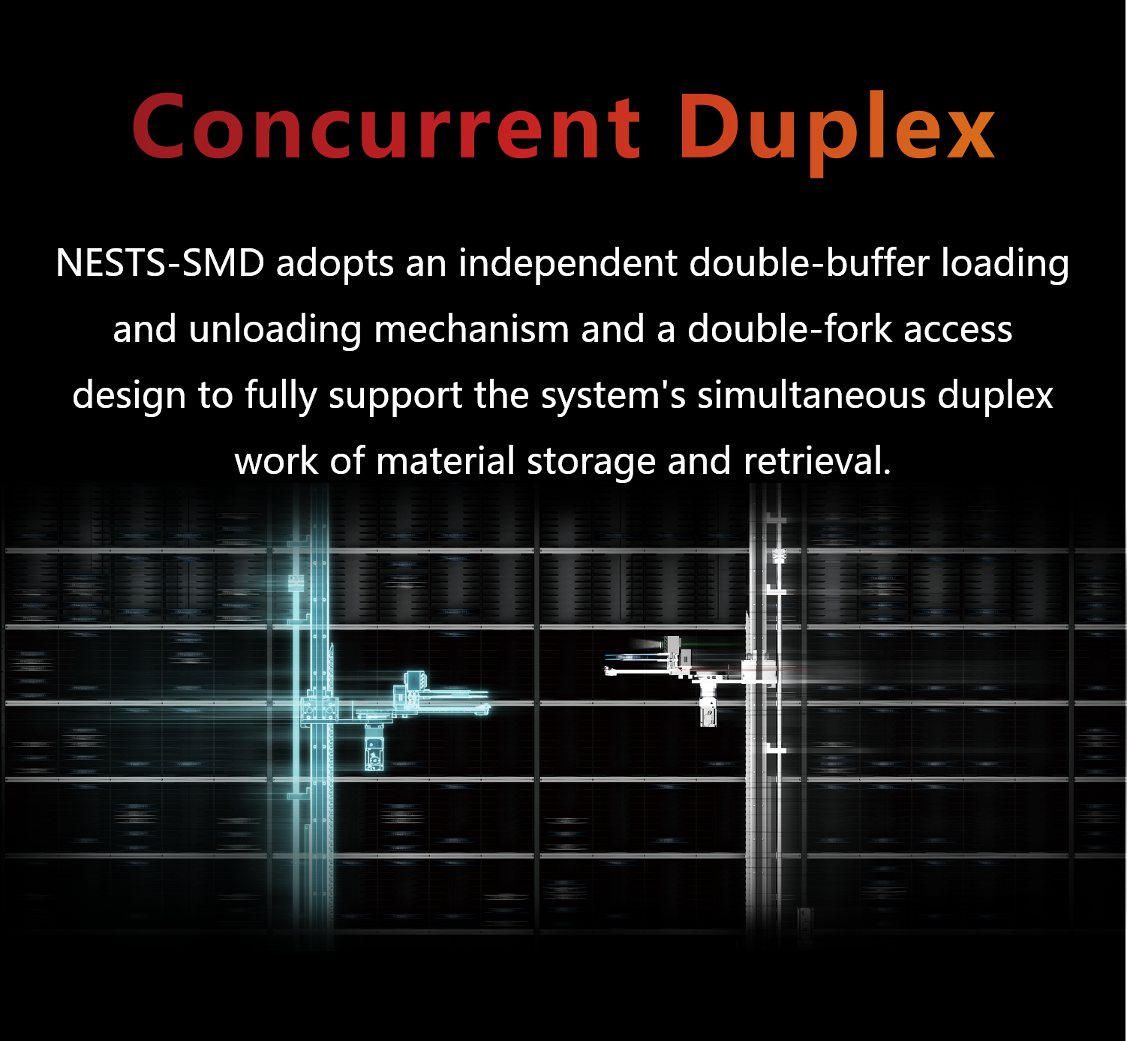

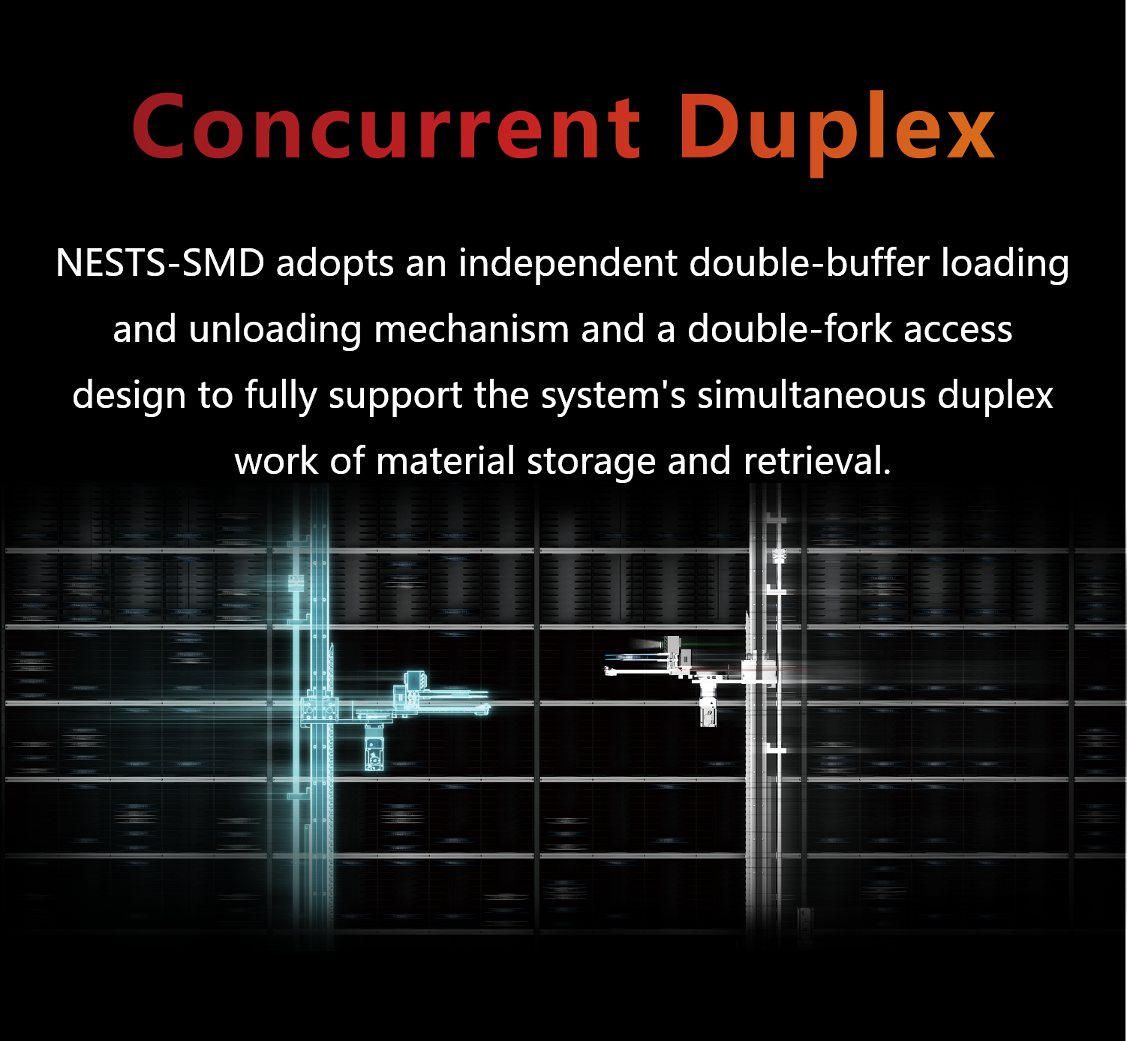

Access duplex

double cache structure, concurrent duplex of picking and storing materials

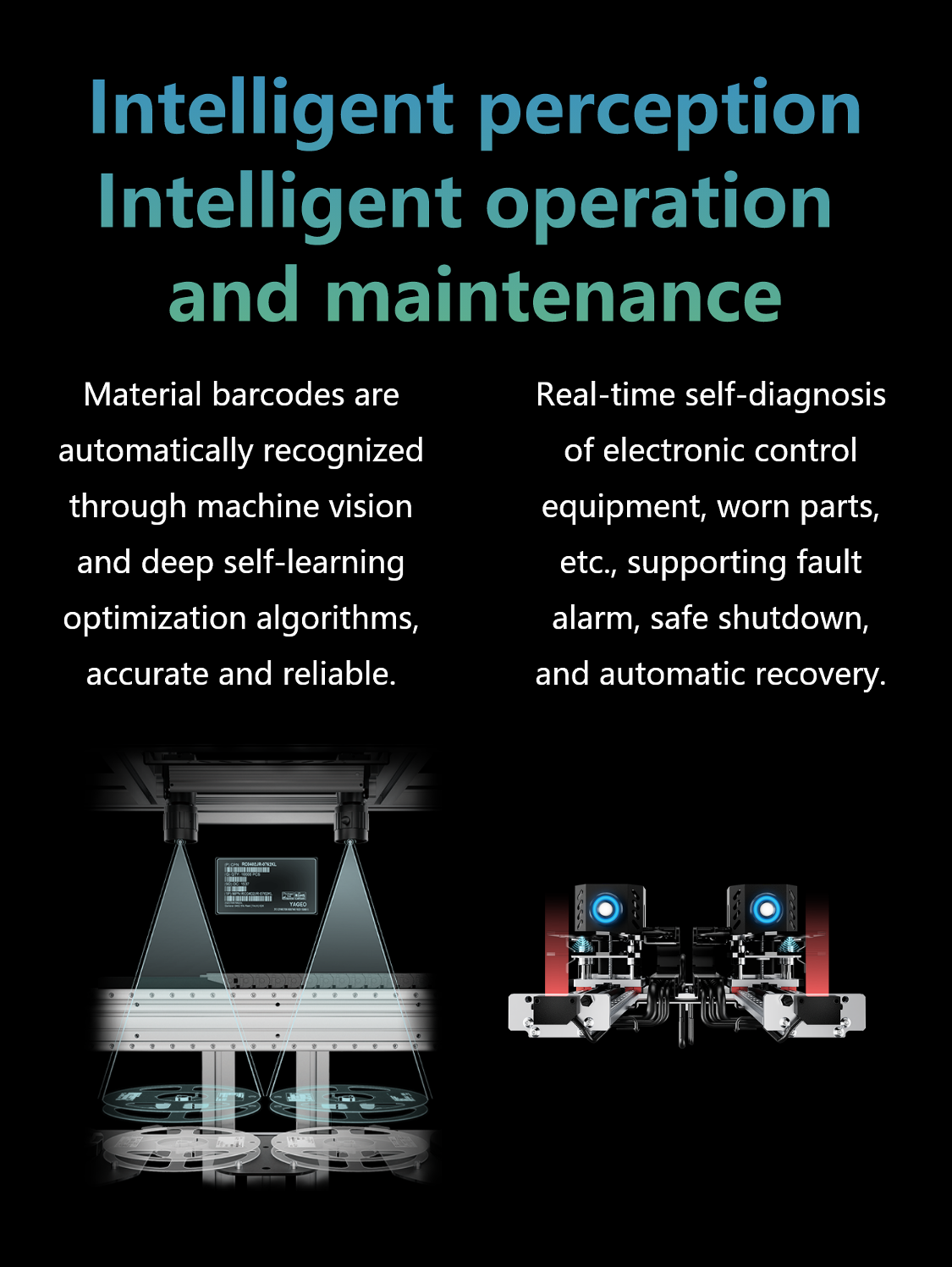

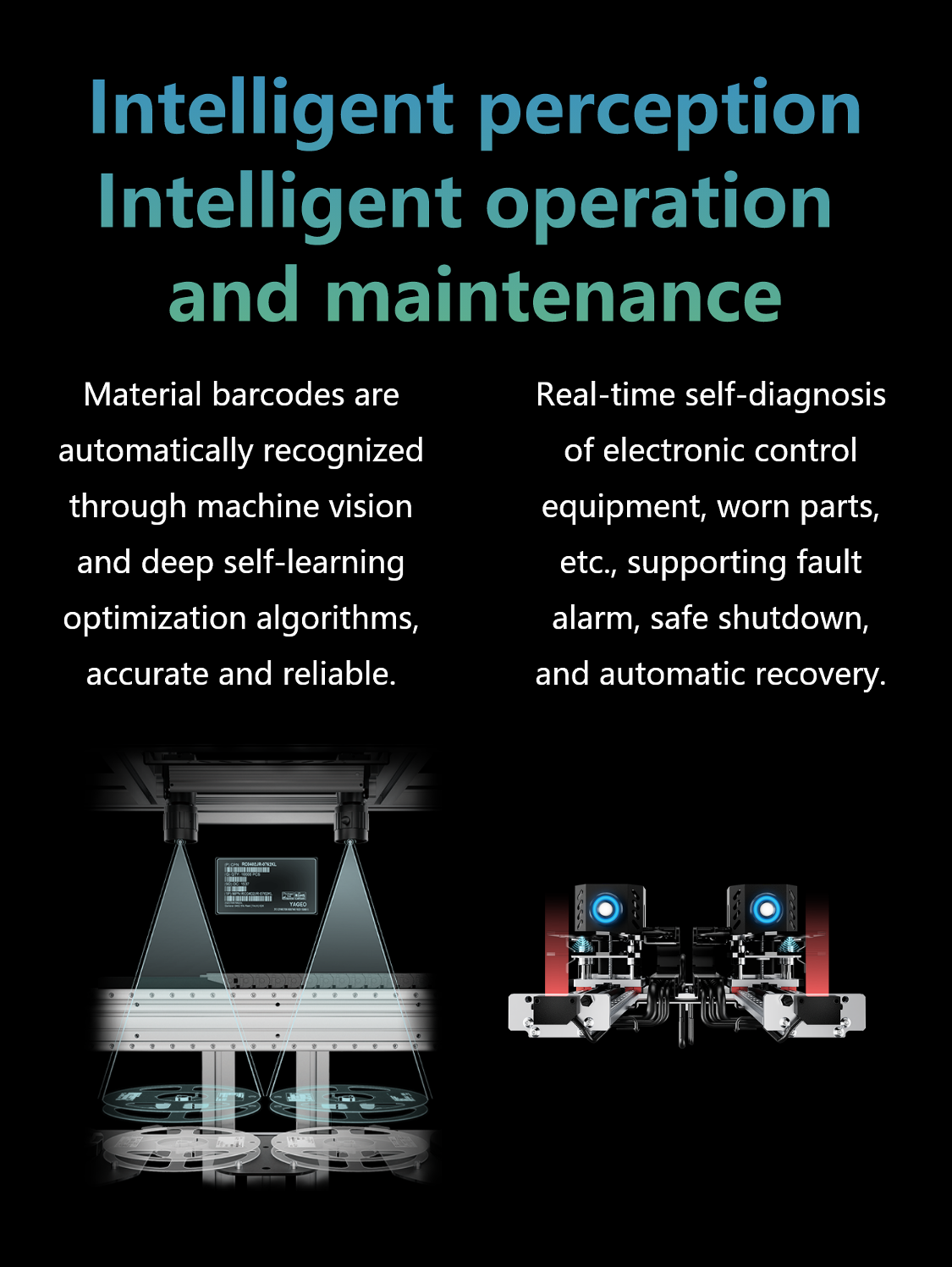

Recognition system

machine vision recognition, deep self-learning optimization algorithm

Electrostatic protection

Anti-static level: :105Ω~109Ω,System-level electrostatic protection

Temperature sensitive monitoring

supports online monitoring of temperature and humidity

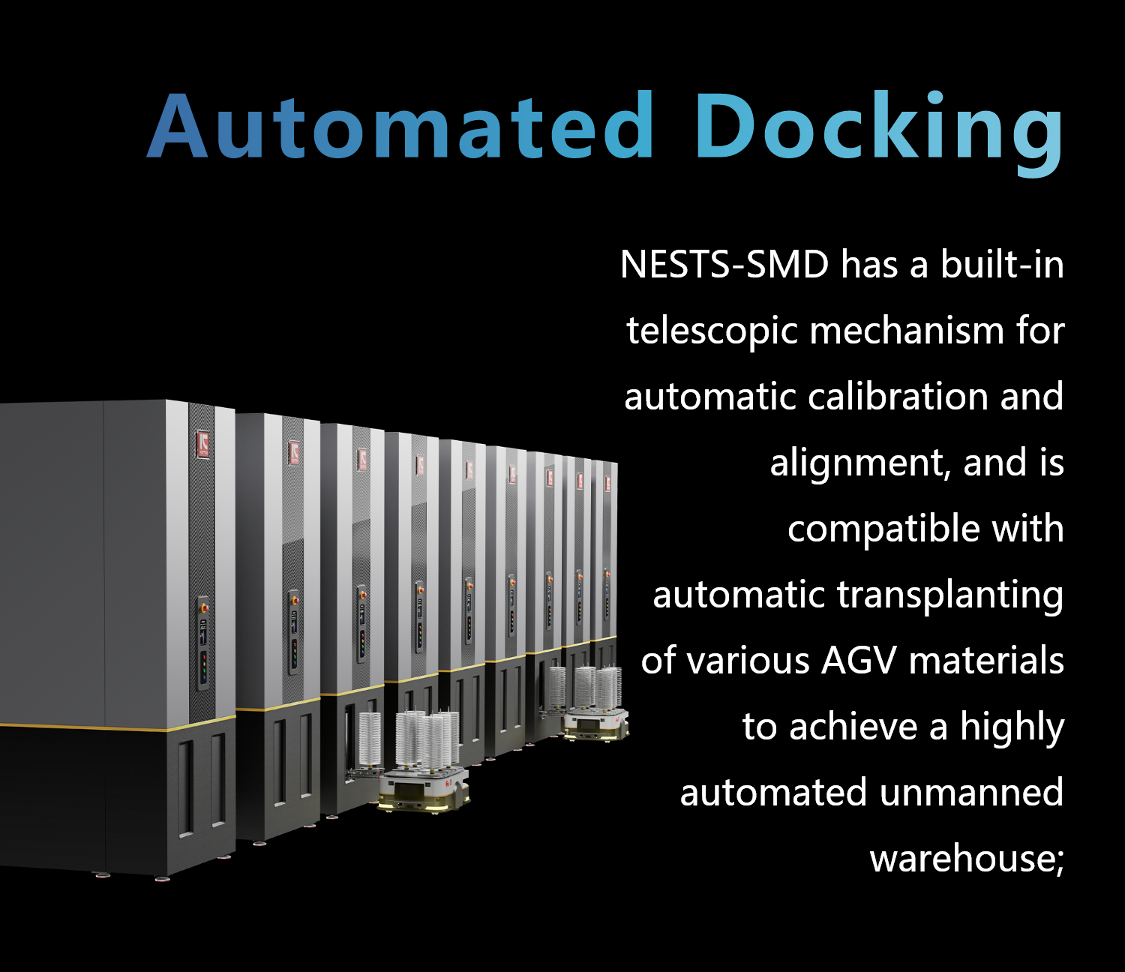

Material loading and unloading mechanism

automatic palletizing, automatic docking, automatic buffering, buffer capacity: 80 reels (7" 8mm reel)

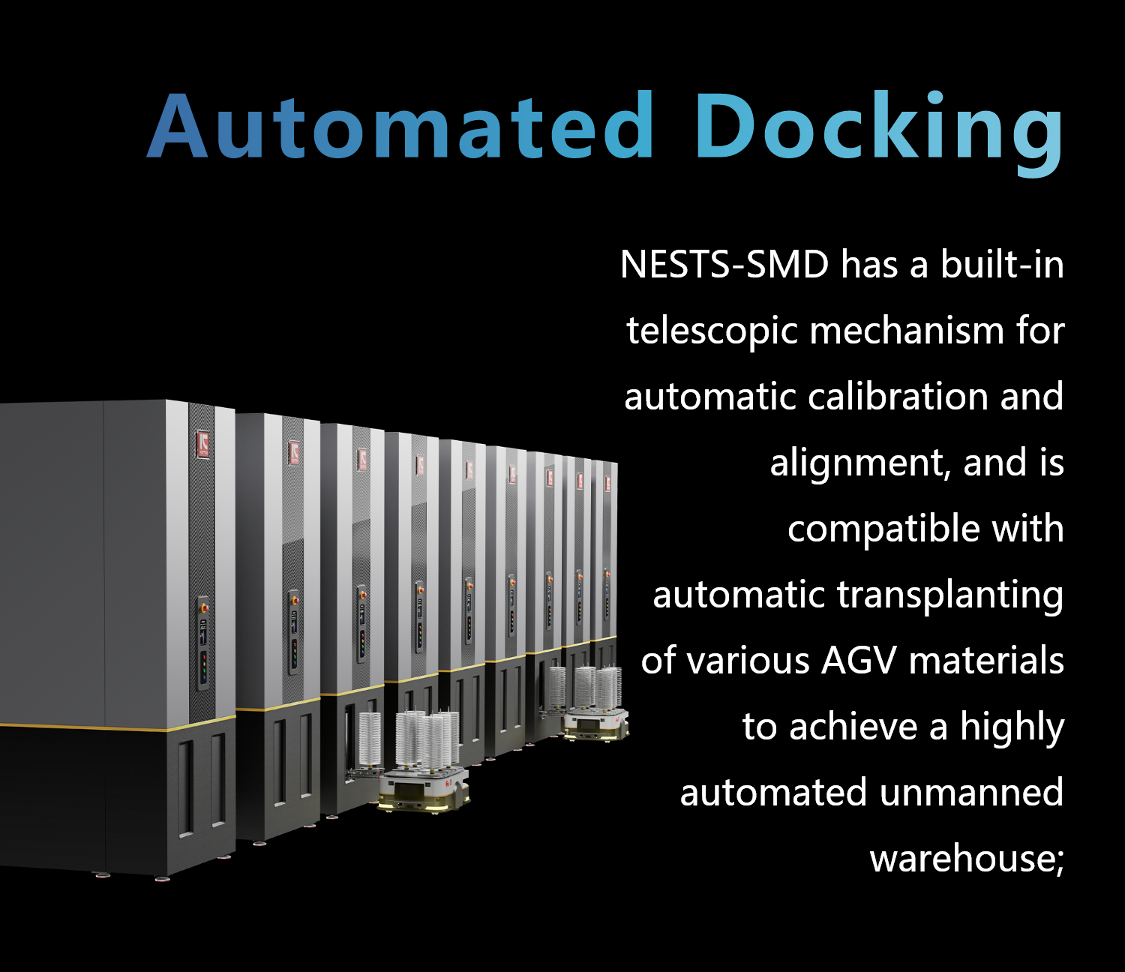

AGV automatic docking

The material buffer is automatically connected to the AGV, AGV positioning accuracy requirements::±10mm

System interface

standardized interfaces such as equipment information, storage location information, operation information, etc., WMS, ERP or MES system optional

Intelligent operation and maintenance

Real-time automatic diagnosis of electronic control equipment, worn parts, etc., supporting fault alarm, safe shutdown, automatic recovery, one-stop intelligent equipment operation and maintenance platform, supporting online equipment monitoring and operation and maintenance prediction;

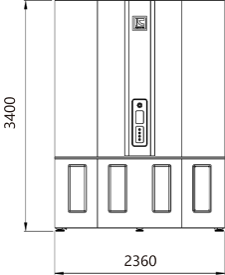

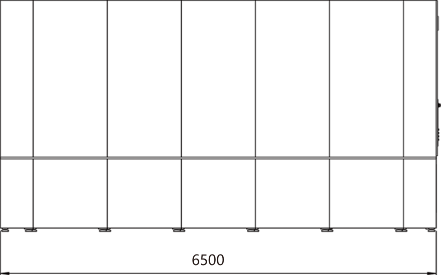

Model

NEST-SMD-DK

Size

L*W*H:6500mm*2360mm*3400mm,supports customization

Electrical parameters

Voltage:AC220V,Power:3200W(MAX),UPS optional

Storage capacity

7" 8mm reels: 12000 reels, compatible with other thickness combination , supports customization.

Throughput capacity

High speed: minimum 1200 reels/h, ultra-quiet mode: minimum 800 reels/h

Access duplex

Four cache structure, concurrent duplex of picking and storing materials

Recognition system

Machine vision recognition, deep self-learning optimization algorithm

Electrostatic protection

Anti-static level: :105Ω~109Ω,System-level electrostatic protection

Temperature sensitive monitoring

Supports online monitoring of temperature and humidity

Material loading and unloading mechanism

Automatic palletizing, automatic docking, automatic buffering, buffer capacity: 160 reels (7" 8mm reel)

AGV automatic docking

The material buffer is automatically connected to the AGV, AGV positioning accuracy requirements::±10mm

System interface

Standardized interfaces such as equipment information, storage location information, operation information, etc., WMS, ERP or MES system optional

Intelligent operation and maintenance

Real-time automatic diagnosis of electronic control equipment, worn parts, etc., supporting fault alarm, safe shutdown, automatic recovery, one-stop intelligent equipment operation and maintenance platform, supporting online equipment monitoring and operation and maintenance prediction;